Metal and Plastics Processing

Go directly to

Hooymans Products maintains a large inventory of metal in sheet, tube, rod, and square formats, along with various types of plastic in sheet and rod materials, including acrylic/plexiglass products. This extensive stock provides significant advantages when initiating new developments with short lead times. All these materials can be processed using various production methods and processes.

Waterjet Cutting and Laser Cutting

Waterjet cutting involves the pressurized spraying of water and abrasive sand, enabling the cutting of virtually any material, thickness, and shape. Laser cutting, on the other hand, is advantageous for larger production volumes compared to waterjet cutting.

Punching and Stamping

Our Amada punch-nibbling machine is able to punch many exact placed holes per minute, commonly used in sheet metal constructions. The machine is also able to nibble exact patterns or punching out holes with high precision. These methods are often used in sheet metal constructions where it is faster to punch a lot of holes with our Amada punch-nibbling machine in relative to water jet cutting for example.

Sheet Metal Processing

Sheet metal is one of the most used production methods inside Hooymans Products. Using our Amada angle benders we can produce folded products. The advantage is that their occurs strength in the material where the plate is being bend. This method is therefore widely used in metal housings and products where strength in lightweight structures is required. Our Amada angle benders can fold up products to a length of 2500 mm.

Turning, Drilling, Milling, and Tapping

The machinery of Hooymans Products consists out of column drilling machines, lathes and milling machines. Specialized staff allows accurate processing of your product. The machines are suitable to process various materials such as: steel, stainless steel, aluminium and a wide range of plastics.

Including our STYLE CNC milling machine we can fully automatic process products with high precision with maximum dimensions of 1500 x 650 x 600 mm.

Various Welding Methods:

Hooymans Products offers a wide range of welding processes: MIG / MAG - TIG - Spot welding - Electrode welding and stud welding. We can weld almost any material, for repairing, to produce singe products or in production series.

Depending on the welding method a weld needs to be finished or not. This can be done by means of acids or grinding. We can also make the weld invisible by post processing. The appearance of a weld can, finally, be just as important as the strength of it.

Robotic welding

In addition to manual welding methods, we utilize a welding robot for TIG welding (aluminum) and plasma welding (steel and stainless steel), ensuring efficiency and consistency in the welding process.

Thermoforming or Vacuum Forming

Thermoforming, also referred to as vacuum forming, is a technique by which plastic sheets are formed by means of heat and a vacuum to form a product. This method ensures that products can be manufactured for endless purposes. At Hooymans Products, we use mainly ABS, Polystyrene and Kydex as materials. After the forming process, the plastics materials first enter a number of hours in the drying cabinet in order to remove remaining moisture. After this process the products are ready.

Additional Capabilities:

We provide services such as deburring, laser engraving, EPS cutting, and stock production, leveraging our extensive inventory of materials to meet diverse needs.

Burring and polishing

Inside Hooymans Products their are many solutions to grind and polish sharp corners or edges. We make use of a vibration table where ceramic stones will scratch sharp edges of the metal or plastic products. The high vibration level of the table results in evenly polished products.

Laser engraving

A wide variety of contours can be engraved on almost all materials with laser engraving. The small diameter of the laser beam makes it possible to be able to engrave sharp angles and very fine lines. Logos and texts are the most common applications of laser engraving at Hooymans Products.

EPS cutting

EPS (Styrofoam) offers many possibilities with regard to transport lightweight protection but can also serve as a visual product. EPS is available in different qualities, the density is higher at a higher quality level. Hooymans Products cuts many customized packaging from EPS.

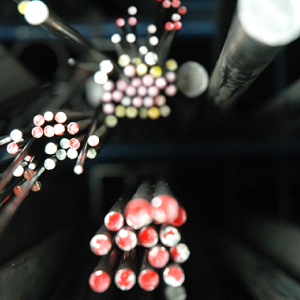

Materials in stock

Hooymans Products has a large amount of various materials in stock. Many kinds of tubes and metal plates of stainless steel, steel and aluminum. Additionally, Hooymans Products has many kinds of plastics and acrylic in stock that can be used for the realization of your product or prototype. The large stock is a great advantage at the start of a development project with short lead times.

Form printing / Pressing

Form printing / pressing uses a die that has a specially designed shape, which must be given to the product to be manufactured. In addition, there is a stamp, which has an opposite shape and therefore fits in the mold. The material to be processed: is placed on the die and held in place by a holder. Then a press presses the stamp down. This clamps the material between the die and punch. As the press moves further down, the material is deformed into the shape of the die.

The image illustrates two aluminum footplates formed using this technique, finished with anodizing, logo printing, and assembly with a rubber part.